Technical Information

The following compilation of technical material is provided as a supplement to the resources still available to the Ducati single cylinder motorcycle owner.

The material presented here is specific to Ducati single-cylinder motorcycles. The information covers both narrow-case and wide case Ducati engines, and hopes to cover many single-cylinder Ducati models.

Motoscrubs.com and its contributors make efforts to ensure the accuracy of the information published on this website. However, the documents and web pages on this site may contain technical inaccuracies or typographical errors. All such documents and web pages are provided "as is.” Motoscrubs.com and its contributors do not warrant the accuracy or reliability of the information presented within, and will not be liable for any errors, omissions, or any losses, injuries, or damages arising from its display or use.

Any information about products, services or merchants is provided for

informational purposes only.

Ducati ® is a registered trademark and is owned by Ducati Motor Holding S.p.A. Motoscrubs.com is not affiliated with Ducati S.p.A.

Parts Books and

Manuals...

Thanks to a valued Forum member who digitized

all the following books for this website.

The parts books and manuals are presented

using the Cooliris©

media browser.

In order to achieve the full benefit of

the Cooliris© Wall, right-click your mouse and choose "Full Screen" to facilitate

parts book navigation.

A large screen helps...

|

Ducati 250cc 5-speed Spare Parts Catalogue ...available NOW. |

|

Ducati D250-250M Spare Parts Catalogue ...available NOW. |

|

Ducati 160 Monza Jr Parts Catalogue ...available NOW. |

|

Ducati 250 Scrambler Spare Parts Catalogue ...available NOW. |

|

Ducati Wide Case Parts Catalogue ...available NOW. |

|

Ducati OHC

Workshop Manual

...available

NOW. |

|

Ducati 450 Group and Lists Parts Supplement ...available NOW. |

![]() 450 Owner's Manual

...in PDF format

450 Owner's Manual

...in PDF format

![]() 350 Scrambler Owner's

manual ...in PDF Format

350 Scrambler Owner's

manual ...in PDF Format

![]() Scrambler 250

Monza 250 Owner's manual ...in PDF Format

Scrambler 250

Monza 250 Owner's manual ...in PDF Format

Ducati Singles Engines...

|

Blueprint for Power Herb Hitch and Jim Hayes Junior's performance modifications for the 250 narrowcase engine. |

|

|

|

Instructions for Use and Maintenance of the [Ducati] 250cc OHC Racing

Motorcycles

|

|

How to Build a Vintage Ducati Racing

Single Engine, carbs, frame + more. Outstanding reference site - build-you-own rear sets, brake stays, etc. |

|

How to Repair a Slipping Narrowcase Kick Start Lever Been there, done it... |

|

Crank End float comments from Bevel Head DSM:

I've been working on the Mach 1 engine. I managed to find

FAG German made 'old stock' bearings (except for one) by shopping around. The

old bearings came out at about 250 deg F in the convection oven save one which

needed some persuasion. After cooling, I cleaned the bearing bores

carefully & reheated. The frozen bearings dropped in easily, but I found the

difficult one to come out did not spin easily when cool. It appears the

greater 'interference fit' on this one was also compressing the bearing and

pushing the outer and inner races closer. When the case was hot it spun

freely, but when cold it was binding. I had another bearing which worked. It

is possible the bore was not as clean as it should of been. Frank Scurria added this:

--- On Thu, 1/7/10, dsm wrote: |

|

Ducati Engine torque values from Master Mechanic/Author Tom Bailey: |

Torque specification is described in the workshop manual as --"Tight".. (Smile) I note that in attending 4 Berliner Ducati schools, all of which were about as half ass as the one described in the book, at no point were torque specifications ever discussed. Further in observing mechanics both at our shop and at the races, I never saw anyone using a torque wrench in the assembly of a Ducati engine, nor did I ever use one...

Interesting in that torque wrenches were religiously used in the assembly of English engines...

I do not think the stretch factor ( which is the reason torque specs are usually given) is critical with regards to joining Ducati cases. The 2 M8 bolts are there to stabilize the case for the cylinder head bolts and the M6 allen heads are there to provide oil tightness. You would think the cylinder head bolts would be somewhat critical and have a torque rating but they are likewise specified as "Tight". Perhaps the aluminum construction of all the pieces (save the cylinder) provides enough expansion that it is not a problem...

Torque ratings on M8 8.0 bolts (as used on the 160 - 350 narrow cases) are in the area of 17 to 18 ft. pounds. I would think 10 percent less would be adequate... Torque ratings on M8 10.0 bolts ( Widecase engines) are in the area of 25 ft. lbs. - Again at least 10 percent less if I were doing it with a

torque wrench...

Stainless steel bolts (often used in modern restos) are weaker than high carbon steel and available in a wide variety of different alloys of different strengths. To find a torque spec for those you weed need to know the alloy...

As far as the M6 allen heads -- use a two inch long allen wrench and do not overdo it. Strip the treads on the bottom of the oil pan and oil will leak out the screw hole! We always coated the center gasket with olive oil. When beads of oil oozed out of the center seam we figured it was tight.

One thing you do NOT want to do is use the screws and bolts to bring the cases together - this will warp the cases. With a wood mallet and a soft wood rod tap the cases until they are in contact, then put the screws in... Use an X pattern for tightening the allen heads. Put the M8's in last.

In other words -- I don't know...and I continue learning that I don't know more everyday.

Ducati Service Bulletin

The following service bulletins are

thanks to Ventodue:

- Bulletin #G-1 Technical Data For The 1962 Ducati 250cc Scrambler

- Bulletin #G-2 Electrical Equipment

- Bulletin #G-3 Electrical Equipment

- Bulletin #G-4 Ducati 250cc Tuning Info.

- 250 Performance Kit 1

- 250 Performance Kit 2

- Berliner #9 "To run without battery or headlight..."

- Berliner #11 Testing the 70-Watt regulator system

- Berliner #12 Increasing headlight effectiveness

- Berliner #13 Simplified testing of the 0400.46.750 voltage regulator

- Berliner #14 "Monza and Sebring recharge circuit page 1"

- Berliner #15 "Monza and Sebring recharge circuit page 2"

- Berliner #16 "Monza and Sebring recharge circuit page 3"

- Berliner #20

Berliner Techincal Service bulletin contains:

- 350 Scrambler service bulletins

- 250 Scrambler and Monza Jr. bulletins

- Diana Mark-3 bulletin

- Ducti Ring Breakage (all models)

And some more service bulletins donated:

- 250 Mark 3 Desmo head conversion (May 10th 1968)

Cycle World 250 Ducati Race Bike Project article published circa 1965-1966.

Ignition Timing of a Ducati Single Carl Liebold's definitive ignition timing guide.

Hear the sound of a 250 revving:

Haynes Ducati

Ducati Workshop Manual

Spare Parts Catalogue

-

Haynes Ducati MK III and Desmo Singles (widecase 1969-1976) ISBN 0 85696 445 X

-

Ducati Workshop Manual, for overhead cam singles (narrowcase up to 1966)

-

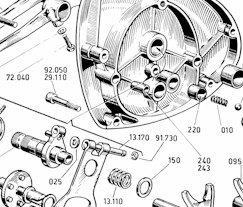

Spare Parts Catalogue Exploded assembly drawings showing every component with part numbers for the 250 GT, Monza, SCR, Mark 3, Monza and Mach1 including engine assembly drawings.

-

Engine Servicing Tools from Desmo online-shop

Ducati Singles Carburetion...

|

|

|

|

|

|

|

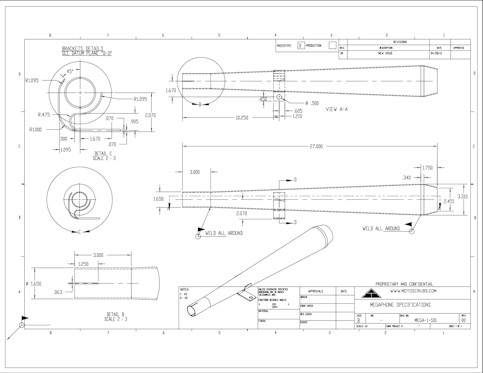

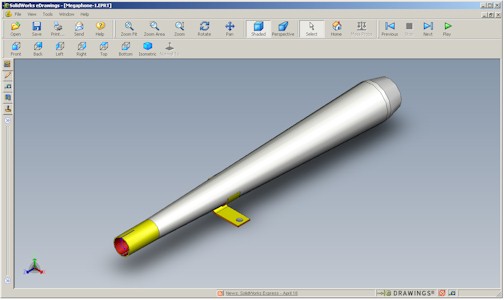

Download a PDF blueprint of the

Mach1/Mark3/Diana megaphone...

Download a fully rotating 3D drawing* of

the Mach1/Mark3/Diana megaphone...

* Requires Solid Works'

free eDrawings viewer available at:

http://www.edrawingsviewer.com/pages/programs/download/index.html

Ducati Singles Electrics...

|

|

|

| Electrical Systems (magneto) Booklet | Electrical Equipment Operation Booklet | Ignition and Flywheel Specifications Booklet |

|

Narrowcase Electrical Systems (magneto) Booklet with schematic |

|

Narrowcase "Magneto" Schematic with diagnostic information (requires PDF reader to view) |

|

|

|

Narrowcase "Regulator" Schematic {a component of the Alternator system} |

|

Narrowcase Electrical Equipment Operation Booklet with schematic |

|

Narrowcase Ignition and Flywheel Specifications Booklet with static timing information |

|

Ducati Service Bulletin

-

Electrical System on the

250 Monza - 5 speed with 6V-60W Alternator

(For testing alternator efficiency)

Ducati Service Bulletin

-

Headlight on 160cc, 250

Scrambler, Mark 3

(Alternator modification to increase light output)

Ducati Service Bulletin

-

Headlight on 160cc Monza

Jr.

(Alternator modification to increase light output)

Ducati Service Bulletin

- Alternator

and Regulator Test

The regulator depicted looks like the wide case style...

Ducati Service Bulletin

-

Headlight Removal

(To run without the battery or headlight on 250 & 350 SCRs with Magneto ignition)

Ducati Service Bulletin

-

SCR Regulator test

(For 250 and 350 SCR with 70 Watt systems)

- Narrowcase (31.5mm) Fork rebuild article

- Narrowcase Forks have a manufacturing date code stamped in

the brake boss.

- A fork assembly's date code may help

to establish the year the motorcycle was built.

Ex: June 1965 appears as "6 65" - In North America most Ducatis were sold and

assigned a model year at the "point of sale" such that every motorcycle a

dealer had was sold as a current model year. The headstock placards were

rarely stamped with the complete model year.

Ex: Anno Di Costruz (Year Of Construction) is stamped with an open-ended year; "196 "

- A fork assembly's date code may help

to establish the year the motorcycle was built.

- Widecase Forks

- Rear Wheel bearings

- The wheel requires two #6202 2RS bearings with shields.

- The cush drive requires two #6004 2RS bearings with shields.