I was reading this 160 Monza Jr project, and cannot believe the gentleman had to trim off the bevel shaft-join bushing to resolve the interference problem. I think it must be something else. If the cylinder gasket was too thin as he thought that causing this interference, then the compression ratio must be sky rocket. Any idea what wrong with it? I think the bevel gear was not shimmed properly causing this interference.

http://advrider.com/index.php?threads/1 ... 288/page-3

Regards,

Brian

Bevel shaft-join bushing too long?

Moderator: ajleone

-

BDang

- Posts: 57

- Joined: Thu Sep 01, 2016 12:35 am

Bevel shaft-join bushing too long?

You do not have the required permissions to view the files attached to this post.

-

Eldert

- Posts: 823

- Joined: Sun Nov 01, 2009 3:23 pm

- Location: Hazerswoude Rijndijk Netherlands

Re: Bevel shaft-join bushing too long?

Hi Brian

could be anything , the distance piece between the 2 7202 bearings that support the lower bevelshaft to long . problem arose in 2011 and is corrected .

this is not the first bevel Craig rebuild so i think the bevels are adjusted properly .

bike is sold and Craig is building a caferacer with a aluminum tank and seat from Evan Wilcox

Eldert

could be anything , the distance piece between the 2 7202 bearings that support the lower bevelshaft to long . problem arose in 2011 and is corrected .

this is not the first bevel Craig rebuild so i think the bevels are adjusted properly .

bike is sold and Craig is building a caferacer with a aluminum tank and seat from Evan Wilcox

Eldert

-

BDang

- Posts: 57

- Joined: Thu Sep 01, 2016 12:35 am

Re: Bevel shaft-join bushing too long?

Hi Eldert,

It was 5 years ago, otherwise I would suggest to Craig checking the spacer between the two 7202 bearings as you pointed out, for authenticity, and shorten it if it was the incorrect piece,instead of modify the stock shaft-join bushing. It is too bad that he also used the long kick-start shaft as a pivot for the clutch basket tool and broke the case. I call this negative maintenance. I was so surprised to see the left side of the engine case so clean. Is this normal for these engines, or this one had a very low mileage?

Regards,

Brian

It was 5 years ago, otherwise I would suggest to Craig checking the spacer between the two 7202 bearings as you pointed out, for authenticity, and shorten it if it was the incorrect piece,instead of modify the stock shaft-join bushing. It is too bad that he also used the long kick-start shaft as a pivot for the clutch basket tool and broke the case. I call this negative maintenance. I was so surprised to see the left side of the engine case so clean. Is this normal for these engines, or this one had a very low mileage?

Regards,

Brian

-

BDang

- Posts: 57

- Joined: Thu Sep 01, 2016 12:35 am

Re: Bevel shaft-join bushing too long?

Study the manual book and I see the said bushing is located between the two snap rings of the lower and upper bevel gears. This means the bearings and their spacer have nothing to do with the bushing interference. The root cause must be either the lower bevel gear is too high or top gear is too low, or a very wrong cylinder gasket was used. In a normal engine how much clearance from bushing to snap ring anyone know? I would think 1mm or more. If the wrong cylinder gasket was causing this then the CR is way dangerously too high.

Regards,

Brian

Regards,

Brian

-

DesmoDog

- Posts: 166

- Joined: Fri Nov 06, 2009 12:36 am

Re: Bevel shaft-join bushing too long?

FWIW the bike ran fine the years I owned it. Started easily, and had performance about equal to other 160s I'd heard about. That bike got ridden pretty hard from the word go and it never missed a beat.

According to the linked post (I don't remember this stuff almost 6 years later) I took off about 0.6mm, and then had about .3mm clearance between the clips and the collar, I doubt there is 1mm there normally. It didn't seem like a major deal, certainly nothing that would make the compression skyrocket. A little bird told me (Fine, it was Tom Bailey's singles buyer's guide) that high compression pistons aren't readily available for the 160 anymore so the trick path to high compression is to take 3mm off the base of the cylinder. The change I was dealing with wasn't anywhere near this and wasn't going to hurt anything. The piston wasn't hitting the head, the valves weren't hitting the piston. The bevels were shimmed correctly going by the stepless planes and I couldn't feel any play in them. Most everything in that bike was original to that engine aside from the gaskets so I doubt any spacers were wrong. I spent time checking things over before I trimmed the collar. The base gasket was the likely culprit unfortunately the engine had been apart for about 4 years at that point and I didn't have the original around to compare anymore. I've seen .8 and .4 listed as gasket thicknesses (a quick google check two minutes ago) and it seems plausible to me that if the original was in the .8 range and the replacement .4 I could easily have run into this situation.

But now I'm rambling. Bottom line, trimming the collar wasn't a knee jerk reaction, there was thought and investigation involved.

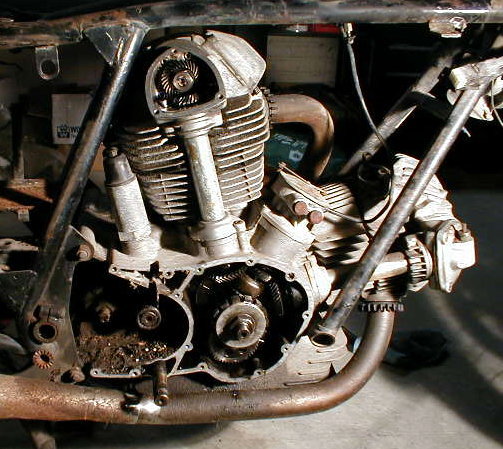

As for the case being clean, maybe the pictures made it look better than it was? In real life it wasn't any cleaner than other aluminum cases I've worked with. I have no idea how many miles were on the bike but it don't recall the interior looking any better or worse than "normal". Here's before and after shots of a roundcase I rebuilt, it was in slightly worse shape than the 160.

As Eldert mentioned, that bike has been sold and now spends most of it's time more or less on display with a bunch of old Porsches and other cars being worked on at a local import auto shop. A few times over the summer the new owner took it out and rode it down the street in front of the shop but that's the extent of the use it will see. The Wilcox bodied bike he mentioned is stalled now, long story short I've gone back to my roots and bought a car project. 1931 Ford Model A chassis with a 1927 Model T roadster body. Speaking of which, if anyone has a turtle deck for the 'T, I need one...

According to the linked post (I don't remember this stuff almost 6 years later) I took off about 0.6mm, and then had about .3mm clearance between the clips and the collar, I doubt there is 1mm there normally. It didn't seem like a major deal, certainly nothing that would make the compression skyrocket. A little bird told me (Fine, it was Tom Bailey's singles buyer's guide) that high compression pistons aren't readily available for the 160 anymore so the trick path to high compression is to take 3mm off the base of the cylinder. The change I was dealing with wasn't anywhere near this and wasn't going to hurt anything. The piston wasn't hitting the head, the valves weren't hitting the piston. The bevels were shimmed correctly going by the stepless planes and I couldn't feel any play in them. Most everything in that bike was original to that engine aside from the gaskets so I doubt any spacers were wrong. I spent time checking things over before I trimmed the collar. The base gasket was the likely culprit unfortunately the engine had been apart for about 4 years at that point and I didn't have the original around to compare anymore. I've seen .8 and .4 listed as gasket thicknesses (a quick google check two minutes ago) and it seems plausible to me that if the original was in the .8 range and the replacement .4 I could easily have run into this situation.

But now I'm rambling. Bottom line, trimming the collar wasn't a knee jerk reaction, there was thought and investigation involved.

As for the case being clean, maybe the pictures made it look better than it was? In real life it wasn't any cleaner than other aluminum cases I've worked with. I have no idea how many miles were on the bike but it don't recall the interior looking any better or worse than "normal". Here's before and after shots of a roundcase I rebuilt, it was in slightly worse shape than the 160.

As Eldert mentioned, that bike has been sold and now spends most of it's time more or less on display with a bunch of old Porsches and other cars being worked on at a local import auto shop. A few times over the summer the new owner took it out and rode it down the street in front of the shop but that's the extent of the use it will see. The Wilcox bodied bike he mentioned is stalled now, long story short I've gone back to my roots and bought a car project. 1931 Ford Model A chassis with a 1927 Model T roadster body. Speaking of which, if anyone has a turtle deck for the 'T, I need one...

-Craig

My 350 project: http://www.motoscrubs.com/forum/viewtopic.php?f=3&t=36

The mighty 160: http://www.motoscrubs.com/forum/viewtopic.php?f=11&t=811&p=5590#p5590

My 350 project: http://www.motoscrubs.com/forum/viewtopic.php?f=3&t=36

The mighty 160: http://www.motoscrubs.com/forum/viewtopic.php?f=11&t=811&p=5590#p5590

Return to “Ducati Singles Main Discussions (& How to Join)”

Who is online

Users browsing this forum: No registered users and 61 guests