Hi Bob, no signs of fuel in the oil. Just metal. Enough to paint a Silver Shotgun!

The oil was maybe 500ks old, the level was normal and looked and smelt like 500km old oil.

I'll post some pictures for you

Crank Pin oil Holes

Moderator: ajleone

-

graeme

- Posts: 1031

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Crank-pin Failure's Possible Root-cause

" no signs of fuel in the oil. Just metal. Enough to paint a Silver Shotgun! "

____ Okay, then in that case, it seems that it wasn't the piston-damage that led to the crank-pin failure.

__ So now I wonder how your PREVIOUS batch of dumped/used sump-oil appeared to be ! _ Did IT also show any signs at all of any metallic-flakes disbursed throughout it, as well ?

Cuz if so (to any degree), then I'm now suspecting that you possibly had/have a motor-case ball-bearing that's gone/going to pot. _ As the ground-up (and much harder) particles from such bearing-failure could've been the root-cause of the damage to BOTH the piston and your crank-pin.

Dukaddy-DUKEs,

-Bob

____ Okay, then in that case, it seems that it wasn't the piston-damage that led to the crank-pin failure.

__ So now I wonder how your PREVIOUS batch of dumped/used sump-oil appeared to be ! _ Did IT also show any signs at all of any metallic-flakes disbursed throughout it, as well ?

Cuz if so (to any degree), then I'm now suspecting that you possibly had/have a motor-case ball-bearing that's gone/going to pot. _ As the ground-up (and much harder) particles from such bearing-failure could've been the root-cause of the damage to BOTH the piston and your crank-pin.

Dukaddy-DUKEs,

-Bob

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

graeme

- Posts: 1031

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

Re: Crank Pin oil Holes

No signs of sparkly bits in the previous oil change.

I try and let drained oil sit for a while to let any "bits" settle so I can see them when the oil is poured out, there were none.

All the bearings and bushes will be replaced.

I've just dismantled the head and washed it out, lots of sparkles but all very small.

Graeme

I try and let drained oil sit for a while to let any "bits" settle so I can see them when the oil is poured out, there were none.

All the bearings and bushes will be replaced.

I've just dismantled the head and washed it out, lots of sparkles but all very small.

Graeme

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Re: Crank Pin oil Holes

" All the bearings and bushes will be replaced. "

____ Okay then,

let us know if you find any of them to be in less than good-useable condition.

Hopeful-Cheers,

-Bob

____ Okay then,

let us know if you find any of them to be in less than good-useable condition.

Hopeful-Cheers,

-Bob

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

graeme

- Posts: 1031

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

Re: Crank Pin oil Holes

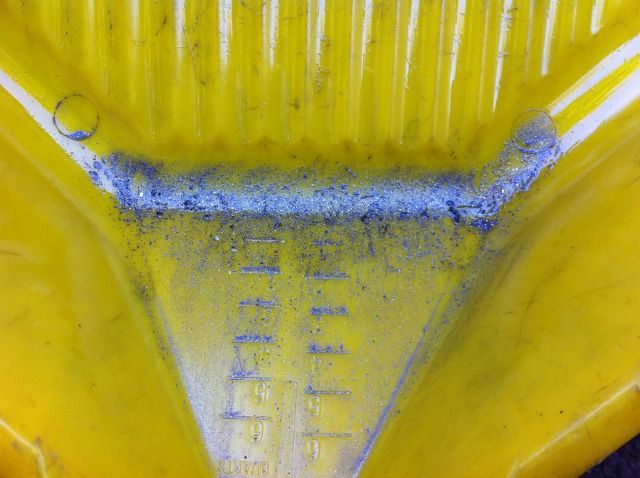

Here is the oil drained from the engine (it was cold) not hot as per a usual oil change.

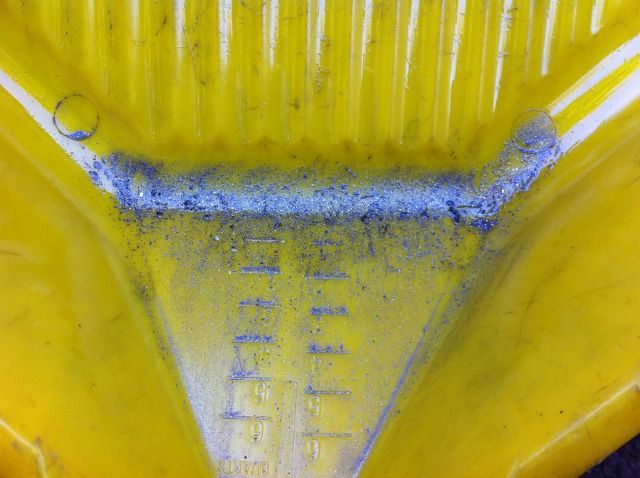

Below is what washed out of the split cases, some small bits of gasket are there too.

Below is what came out of the sludge trap, there is a long magnet with shiney bits attached.

Below is what washed out of the 2 crank halves and the stripped oil pump.

There's more metal than what came from the failed crank pin, some is alloy and some is from the crank end (oil pump end) and some will no doubt be other bearing material.

There were no usual rumblings from the crank pin and bearing to warn of impending wallet torture like I've heard in the past from big end or main failure. (I've never had a big end fail before, but heard them)

By the time it made itself known the damage was done.

I'll endevour to fit magnets in the future to all my singles. (2)

A friend in Ireland showed me a Magnom inline filter, and a magnetic strainer in place of the standard gause filter that are worth considering.

Anyone else have any suggestions?

Graeme

Below is what washed out of the split cases, some small bits of gasket are there too.

Below is what came out of the sludge trap, there is a long magnet with shiney bits attached.

Below is what washed out of the 2 crank halves and the stripped oil pump.

There's more metal than what came from the failed crank pin, some is alloy and some is from the crank end (oil pump end) and some will no doubt be other bearing material.

There were no usual rumblings from the crank pin and bearing to warn of impending wallet torture like I've heard in the past from big end or main failure. (I've never had a big end fail before, but heard them)

By the time it made itself known the damage was done.

I'll endevour to fit magnets in the future to all my singles. (2)

A friend in Ireland showed me a Magnom inline filter, and a magnetic strainer in place of the standard gause filter that are worth considering.

Anyone else have any suggestions?

Graeme

-

Single duck

- Posts: 32

- Joined: Tue Jan 12, 2010 11:30 am

- Location: North Wales

- Contact:

Re: Crank Pin oil Holes

Graeme, first of all commiserations, looks bad (and expensive)

These won't help you now, but could in future give you a bit more pre-warning of impending doom;

http://www.widecase.com/special-or-race-products/magnetic-dipstick/prod_56.html

http://www.widecase.com/special-or-race-products/sump-filter/prod_89.html

These won't help you now, but could in future give you a bit more pre-warning of impending doom;

http://www.widecase.com/special-or-race-products/magnetic-dipstick/prod_56.html

http://www.widecase.com/special-or-race-products/sump-filter/prod_89.html

Howard

Capo di tutti capo at http://www.widecase.com

Supreme Commander at http://www.discovolantemoto.co.uk

Capo di tutti capo at http://www.widecase.com

Supreme Commander at http://www.discovolantemoto.co.uk

-

graeme

- Posts: 1031

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

Re: Crank Pin oil Holes

Thanks Howard,

I needed something to do, just didn't plan on this.

I'm not pissed as I've had many years of fun on this bike, and most have been hard, so it's time for some rebuilding and repaying for the years of fun.

Ta for the links, the gauze filter looks like the one Dave from Belfast showed me with a rare earth magnet fitted to the internals.

One reason I didn't buy one earlier is I was questioning how much cold oil could pass through the finer gauze?

The magnet on the dip stick I've done with a piece of hose so the magnet is at the bottom of the cases. (for next time)

Graeme

I needed something to do, just didn't plan on this.

I'm not pissed as I've had many years of fun on this bike, and most have been hard, so it's time for some rebuilding and repaying for the years of fun.

Ta for the links, the gauze filter looks like the one Dave from Belfast showed me with a rare earth magnet fitted to the internals.

One reason I didn't buy one earlier is I was questioning how much cold oil could pass through the finer gauze?

The magnet on the dip stick I've done with a piece of hose so the magnet is at the bottom of the cases. (for next time)

Graeme

-

DewCatTea-Bob

- Posts: 2897

- Joined: Sun Nov 01, 2009 10:53 am

- Location: Near SE side of Lake Michigan

Oil-filtering

" There's more metal than what came from the failed crank pin, some is alloy and some is from the crank end (oil pump end) and some will no doubt be other bearing material.

Anyone else have any suggestions? "

____ You had mentioned also finding same up-within your cyl.head...

So if any of those particles up in there were also as large, then I'll bet your oil-filter/screen-tube was warped ! ...

A common-problem with that filter/screen-tube/drain-plug is that when it's reinserted back-into place in the crankcase, it's nose/tip-end doesn't always simply fall-home & into it's intended place (inside the oil-pump's inlet-hole), thus allowing unfiltered oil to enter into the oil-pump.

__ I've already warned of this possibility before, that if ya'r plastic screen-tube doesn't appear to be nice & straight (when removed), then it was likely (at-least at some time in it's life), inserted & tightened-down without proper care (and forced to become warped). ...

When the screen-tube is inserted all the way in (properly), it should be able to be screwed-inward by hand ALL THE WAY in, (with a wrench only needed for just the last half-turn) !

However if the screen-tube's threads only screw-in about half-way when some resistance is then encountered, then that means that the tube's tip-end/nose is not entering into it's place in the oil-pump's inlet-hole !

So at that point (of encountered resistance), (if it indeed happens to occur), the screen-tube's threaded-plug end should be twisted back & forth and finessed until ya feel the resistance get pressed-away, and thus-then it's nose-tip has been successfully inserted into it's expected normal-location/place inside the pump's inlet-hole (and not forced to become warped-up into a crammed-space).

__ So do you have a picture of your oil screen-tube for us to have a look at ?

Hopeful-Cheers,

-Bob

Anyone else have any suggestions? "

____ You had mentioned also finding same up-within your cyl.head...

So if any of those particles up in there were also as large, then I'll bet your oil-filter/screen-tube was warped ! ...

A common-problem with that filter/screen-tube/drain-plug is that when it's reinserted back-into place in the crankcase, it's nose/tip-end doesn't always simply fall-home & into it's intended place (inside the oil-pump's inlet-hole), thus allowing unfiltered oil to enter into the oil-pump.

__ I've already warned of this possibility before, that if ya'r plastic screen-tube doesn't appear to be nice & straight (when removed), then it was likely (at-least at some time in it's life), inserted & tightened-down without proper care (and forced to become warped). ...

When the screen-tube is inserted all the way in (properly), it should be able to be screwed-inward by hand ALL THE WAY in, (with a wrench only needed for just the last half-turn) !

However if the screen-tube's threads only screw-in about half-way when some resistance is then encountered, then that means that the tube's tip-end/nose is not entering into it's place in the oil-pump's inlet-hole !

So at that point (of encountered resistance), (if it indeed happens to occur), the screen-tube's threaded-plug end should be twisted back & forth and finessed until ya feel the resistance get pressed-away, and thus-then it's nose-tip has been successfully inserted into it's expected normal-location/place inside the pump's inlet-hole (and not forced to become warped-up into a crammed-space).

__ So do you have a picture of your oil screen-tube for us to have a look at ?

Hopeful-Cheers,

-Bob

PLEASE NOTE... If this-post is not-yet signed-off with '-Bob', then I'm still in the process of completing it,, and if not also included with 'DCT' near bottom as well, then I may edit this post's wording at a later time. - Dct.Bob

-

graeme

- Posts: 1031

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

Re: Crank Pin oil Holes

Tomorrow, it wasn't the strainers fault, the particles in the oil pump and downstream were all small.

-

graeme

- Posts: 1031

- Joined: Sun Mar 25, 2012 12:00 am

- Location: Tasmania Australia

Return to “Ducati Singles Main Discussions (& How to Join)”

Who is online

Users browsing this forum: Majestic-12 [Bot] and 46 guests